Automated RTG Application

Choose the right level of automation for you

New degrees of freedom through automating rubber-tyred gantry cranes

Rubber-tyred gantry (RTG) cranes are the most popular equipment choice for container stacking at terminals around the world, especially where high-capacity stacking and good manoeuvrability are key requirements. How far you take automation will depend on your application requirements, and at Kalmar we give you the freedom to choose the mix that’s right for you, from fully manual to semi-automated or highly automated.

Path to RTG automation webinar

Watch our on-demand webinar to learn more about RTG automation

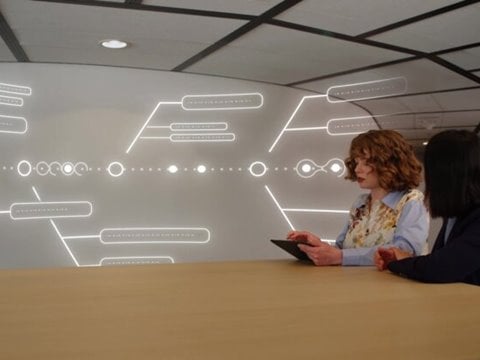

A flexible and scalable open automation system

Kalmar’s automation system Kalmar One enables job management and routing for RTGs. The onboard system guides the crane to its next position, either in semi-automated mode with the driver manually feeding in commands or automatically when the interface to TOS has been set up. Safety is our first design principle in all automated solutions. It can be further improved with anti-truck lifting (which prevents a locked chassis from being accidentally lifted), and stack profiling (which eliminates the risk of containers being accidentally knocked off the stack). Kalmar RTG automation can be integrated with third-party cranes.

You need to accept targeting cookies before you can view the YouTube content. Those cookies may be used to show you relevant content and adverts. Click the button “Cookie Settings” to manage your preference.

You need to accept targeting cookies before you can view the YouTube content. Those cookies may be used to show you relevant content and adverts. Click the button “Cookie Settings” to manage your preference.

Latest from News & Insights

You need to accept targeting cookies before you can view the YouTube content. Those cookies may be used to show you relevant content and adverts. Click the button “Cookie Settings” to manage your preference.