Kalmar helps make Port of Brisbane a world-class automated terminal

DP World and Kalmar's cooperation has made the Port of Brisbane one of the most highly automated facilities in the world. Automation will enable an increase in the terminal's annual capacity from 600,000 to 900,000 TEU, as well as improved customer service.

The challenge

The competitive environment at the Port of Brisbane became tougher with the arrival of a third operator in 2012. The port's other two operators had already implemented automated systems and equipment. DPW Brisbane realised that it would have to make more efficient use of its terminal space while maintaining the highest standards of safety, complying with maritime transport security regulations and delivering excellent customer service.

The solution

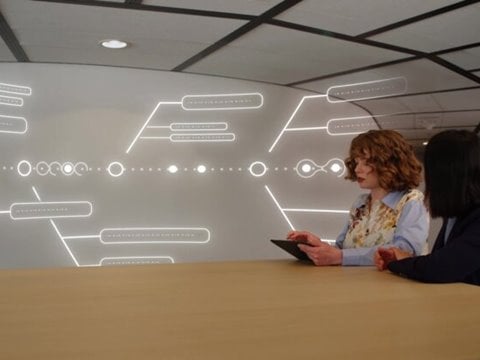

Containers are transferred by manned straddle carriers from the quay crane to the interchange area at the waterside end of a module serviced by automated stacking cranes (ASCs). Fourteen Kalmar straddle carriers operate between the ship-to-shore cranes and ASCs to transfer containers between vessels and the land. Kalmar Automated Truck Handling automates the landside operations.

The result

DP World Brisbane has adopted the latest automation technology from Kalmar and Navis to ensure fully integrated operations that deliver optimum productivity and reduce operational costs. The project will increase the terminal's capacity from 600,000 to 900,000 TEU and it will be one of the most highly automated in the world, ready to meet the shifting demands of the business – both today and tomorrow.

"Ultimately, we felt that a combination of ASCs and straddle carriers would not only provide the best financial return on investment but also the highest level of waterside productivity," says Mark Hulme, COO, DP World Australia.

Related articles

Further reading

Subscribe and receive updates in your email

Subscribe