Future of ASC – A look beyond electrification

The interest towards electric powered equipment is increasing – not only because of its environmentally friendly aspects – but also due to many additional positive spin-offs it provides like noise reduction, ease of maintenance and automation. We at Kalmar were able to get rid of the diesel engine onboard an Automatic Stacking Crane (ASC) by using cable reel or buss-bar systems, and now that this has been sorted out one can start to wonder what’s the next step for the ASCs?

Emission reduction should be the key driver for R&D work. As we all know, electricity must come from somewhere. To develop truly environmentally sound products in the future, we need to think about the whole energy production chain. Steps like recovery of hoisting and braking energy are good additions. As battery technology and prices start to be on a feasible level, one can build environmentally friendlier equipment with attractive prices for horizontal transportation.

But let’s return back to the ASCs. To develop the product further, we need to think big at first. Let’s look at the whole ASC as such. Weight is obviously a factor that affects many dimensions of the terminal design. Starting from getting savings in civil engineering side, the size of the equipment has also an effect on dimensioning of many of the components. Last but not least, by developing dimensions in a positive way, we are able to gain savings in manufacturing cost also through reduced steel consumption.

Energy consumption can be reduced by diminishing the wind effect that comes from the overall design and outlook of the crane. The rule of thumb is that what looks good usually also works well. New materials and components enable engineers to break free from the traditional ‘square’ thinking for developing an effective solution. To achieve this, we must include industrial designers as part of normal R&D work.

One additional area to look at is solar cell technology. The technology has taken major steps during the past years. It has become so cheap and easy to operate that even consumers are buying the idea for their everyday use. Here the number of machines pays an important role. In a terminal there are tens of ASCs and each of them can be equipped with solar cells integrated into the base design to build a substantial environmentally sound energy source for the whole terminal.

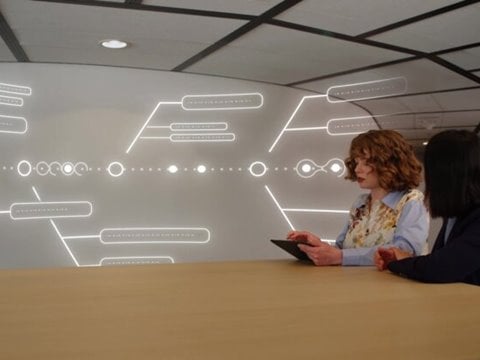

By combining these new thoughts and items, future ASC could look like recent Kalmar concept study:

Annual average solar radiation depends on the location. See below for world map. The example calculation here is for New South Wales, Australia where H = 1637 kWh/a according to NASA database.

SolarGIS © 2013 GeoModel Solar, [CC BY-SA 3.0], via Wikimedia Commons

With system and location described above, per ASC the total produced solar energy is around 54.000 kWh/year. Rough estimate for yearly energy consumption with feedback taken into account based on real operational measurement is around 400 000 kWh calculated with 100 000 moves.

For 100 000 moves / year operation, solar panels can ideally reduce the energy consumption by 13,3% annually. However this is not all.

When the crane is idle and sun radiation is high, some of the power generated by solar system needs to be fed back to the grid to be used other cranes or equipment or stored or consumed in some other way. It can be used in other ASC’s in Air-conditioning or any other use in the terminal. Battery storage systems on ASC’s define how much can be stored there etc. Depending on the size and terminal other activities where best utilize solar energy to minimize the environmental impact.

As a summary, Kalmar’s vision for environmentally sound future terminal can be summarised:

- We must have electrically powered offering in ALL container handling machine types.

- We must continue investing in environmentally friendly solutions

- Emission reduction is a main criteria in all R&D efforts

- Noise reduction is also in our focus

- …and all this needs to be done with competitive market prices.

So, many opportunities available for ASCs, but what would you prioritise? Let us know you opinion and comments to the subject. Join the discussion.

Related articles

Subscribe and receive updates in your email

Subscribe